HFH

Sustainability Optimization with CIP

2,087 views

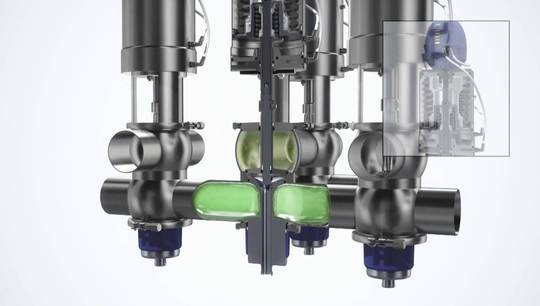

Food and beverage companies are setting increasingly ambitious sustainability targets, but without optimizing cleaning-in-place technologies first, meeting these targets can be an uphill battle. On average, 20% of a plant's energy use is needed for CIP. Changing your valves and controls to Alfa Laval for burst seat reduces your energy consumption, water, and CIP use.

You can also gain efficiencies from optimizing tank cleaning and replacing pumps and agitators with energy-efficient Alfa Laval models. Burst seat lift cleaning involves quick and repetitive opening and closing of the seat. Change your valves and controls for burst seat lift to reduce CIP losses, and with that, energy. Replace your spray balls with Alfa Laval rotary jet heads cleaning to reduce CIP flow and time, and therefore, energy.

Upgrading your pump to our latest technology further ensures large energy savings. Alfa Laval product innovations help you reduce energy, water, and CIP in your plant. That is what we call sustainable optimization. Upgrading to Alfa Laval equipment can reduce energy by up to 80% and water and CIP use by up to 90%. Achieve profitability and sustainability faster.